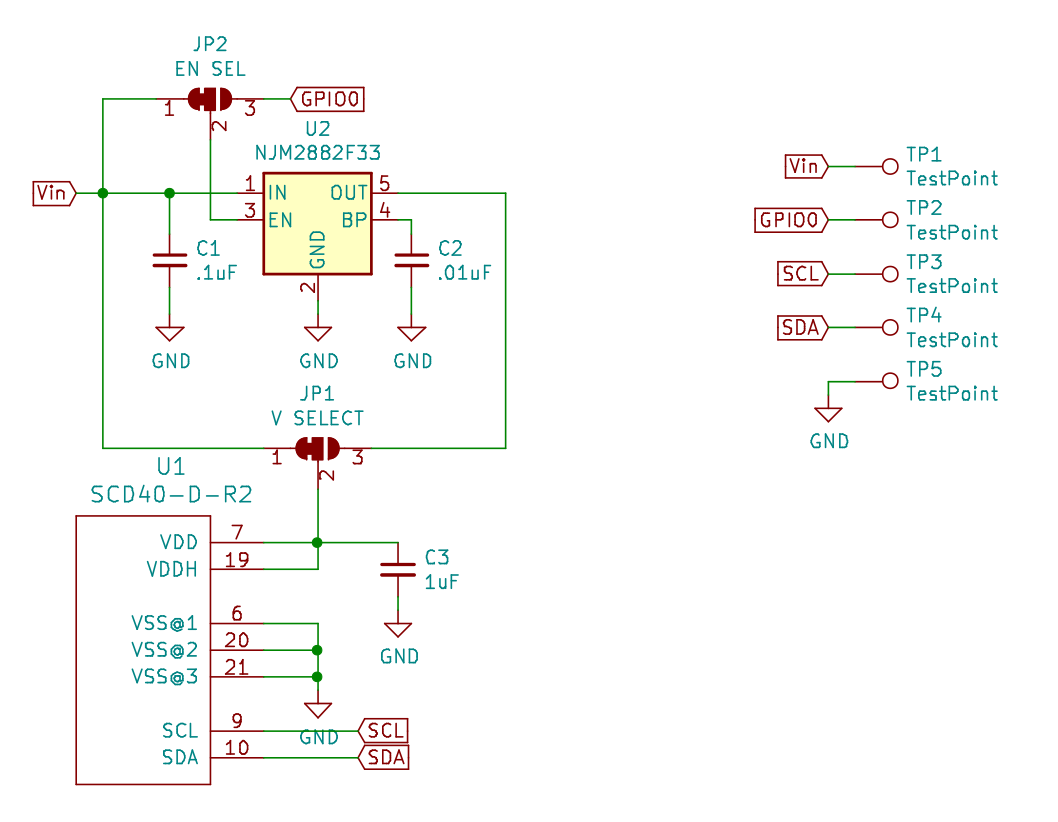

A small 10.3mm x 17mm PCB to mount the Sensirion SCD40/41 CO₂ sensor on. It contains footprints to optionally add a 3.3v LDO regulator and some extra capacitors to better decouple the power supply.

This board is designed to be used with the Watchy Open Source E-Paper Watch. A matching case can be found at cscott/watchy-co2-case, and a watchface using this board can be found at cscott/watchy-c4,

When wiring to Watchy, the SCL/SDA/GND inputs should be wired to the appropriate test points on the Watchy PCB back, as shown below.

For Vin, there are three options:

-

The Vin input can be connected to the +3V3 test point above, with JP1 in its default UNREG position. This shares the 3.3V power supply with the main ESP32. It may (or may not) be too noisy for best SCD40 accuracy.

-

The Vin input can be connected directly to the battery +BATT at one of the positions highlighted in pink below. JP1 would be left in its default UNREG position. This provides the best battery efficiency (the SCD40 can tolerate the higher voltage level), but (depending on the battery internal resistance) again may be too noisy for best SCD40 accuracy. However, this is the configuration I have used in the watches I've assembled.

- The Vin input can be connected directly to the battery +BATT as above, and JP1 moved to its alternate REG position. This powers the SCD40 by its own dedicated LDO regulator, ensuring the quietest possible power supply. In this configuration you can swap JP2 as well to its GPIO0 position and wire up the GPIO0 input to control the power to the SCD40. See the pink highlight below for the test point location which provides access to GPIO0.

The CP1 and CP3 capacitors will provide useful decoupling in all three configurations, although (depending on noise measurements) they may not be required. All three capacitors and U2 are required in configuration three.

Here's a digikey link for all components.

Note that this board will work with the lower-cost SCD40 sensor, and gets about a day of battery life in this configuration with the stock Watchy battery, reading CO₂ levels every 30 seconds. The slightly more expensive SCD41 sensor has the exact same pinout and footprint, but contains a lower-power mode where it can read the sensor every 5 minutes instead, and power consumption drops from 3.2mA to 0.5mA. (In October 2021 the SCD42 was added to the product lineup which is also footprint-compatible, but this part drops the low power modes and requires 15mA which would make it incompatible with wearable use.)

This board was designed using KiCad 5.

(See also this doc from TI on decoupling techniques using a ferrite bead if further noise reduction is necessary. The Sensirion datasheet for the SCD40 suggests less than 30mV of power supply noise.)

Note that I've connected GPIO in these photos, even though I'm not using

regulator (I'm using power option 2). I also added an extra capacitor,

whose high side is supposed to be connected to pins 5 and 6 of the CP2104

to fix the dreaded "USB death" problem of the first release of the Watchy,

but instead (due to a confusion I had about the PWR_FLAG symbol on the

Watchy schematic, it's connected across the input to U2, the watchy voltage

regulator -- which could also use a capacitor to stabilize the regulator,

but wasn't what I was intending to do...

I also had issues with the watchy button switches popping open because they are not supported on the bottom side; the orangish bits of plastic in these photos are my impromptu shims to allow the bottom side of the switches to be supported by the bottom case half.